Sustainability within Probottlers

Probottlers produces carbonated soft drinks (CSD) and cordials at a factory located in Ruwa outside Harare.

The company was launched in 2013 under the Bally House Crush and Cordial range and produces a CSD "Fizzi" as well as mixers under the St Clairs range.

Key Sustainability Highlights

- Probottlers have received the purified drinking water compliance certificate from the Standards Authority of Zimbabwe (SAZ) to manufacture purified drinking water and use SAZ's logo as a mark of compliance.

- Probottlers is the largest consumer of plastic bottles packaging in the Group and has been focusing on reduced plastic use in F2024. The width and thickness of the labels used has been reduced as well as the individual weight of Probottlers' H2G0 water bottle. The weight of each bottle has been reduced from 22g to a 16g preform for carbonated soft drinks, reducing the amount of plastic used by 25%. By also reducing the grammage of HDPE used in closures from 2.5g to 2.2g Probottlers reduced HDPE usage by 12%.

- Probottlers continue to improve energy management with the installation of a new energy efficient blender and with the installation of an energy logger device to track energy consumption of specific high energy utilisation equipment.

- The installation of a water recovery system from the conveyors and fillers has resulted in reduced water requirements.

- Probottlers has increased its loading rate on finished goods from 19.8 to 27 tonnes on a 30- tonner truck which has reduced the business' current carbon footprint per truck.

Note:

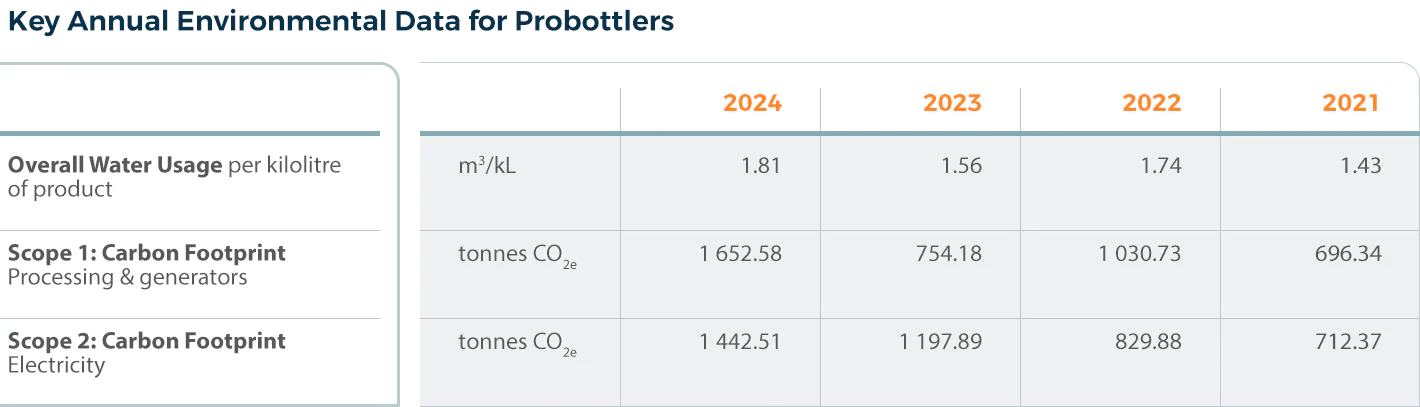

- For the historical data to be comparable, the Scope 1 Carbon Footprint for 2021 to 2023 has been recalculated using the Department for Environment, Food and Rural Affairs (UK) (DEFRA) factors for 2024.