Promoting Social Responsibility Within our Supply Chain

Overview

Fair operating practice is a core component of social responsibility. Fair operating practices relate to the Group’s relationships with government agencies, regulators, partners, suppliers, service providers, contractors, customers, competitors and member associations.

Responsible behaviour is fundamental to establishing and sustaining legitimate and productive relationships within the Group’s supply chain.

Supply Chain Management

Across its supply chain, the Group relies on a wide range of suppliers and service providers to support the production, distribution and sale of products that are central to the business. Our goal is to ensure that all Group sourcing, procurement and supplier-related dealings are conducted in a responsible and accountable manner at every stage of the operations - from the production of raw materials to the delivery of finished products - minimising risk while maintaining value, quality brands and reputation.

This is achieved through adherence to the Group policies and procedures on procurement, supplier management, code of conduct, human rights, ethics and environment. Management of the supply chain is based on the Group’s overall management approach.

Responsible Sourcing and Procurement

The Group focusses on fostering relationships and collaborations with suppliers who are in line with our ethical, environmental and social values. The Group’s current supplier assurance process involves the screening of suppliers based on track records and consideration of issues such as legal compliance, health, safety, labour practices, corruption, environmental impact, social behaviour and human rights practices along with any complaint or grievance mechanisms. We engage suppliers through supplier meetings, briefings, questionnaires, contractual reviews, audits and training to understand their practices and guide improvement of their procedures. Any major supplier non compliances are reported and addressed preferably through mandatory corrective actions as well as the provision of support activities such as capacity building, or subsequent termination of contracts.

The Group expects suppliers to adhere to national laws, international health and safety standards and ethics. In managing risk, our suppliers are introduced to international standards requirements and evaluation criteria so as to sustain our brands and reputation, as well as to improve their own systems.

However, the Group has recognised the need for a more robust system for supplier assurance and supplier selection decisions. This includes the development of more comprehensive supplier assessments and evaluations based on their environmental and social performance.

The Group’s procurement practices are closely monitored, evaluated and improved through internal reviews to ensure adherence with our Group values and best practice.

Raw Materials

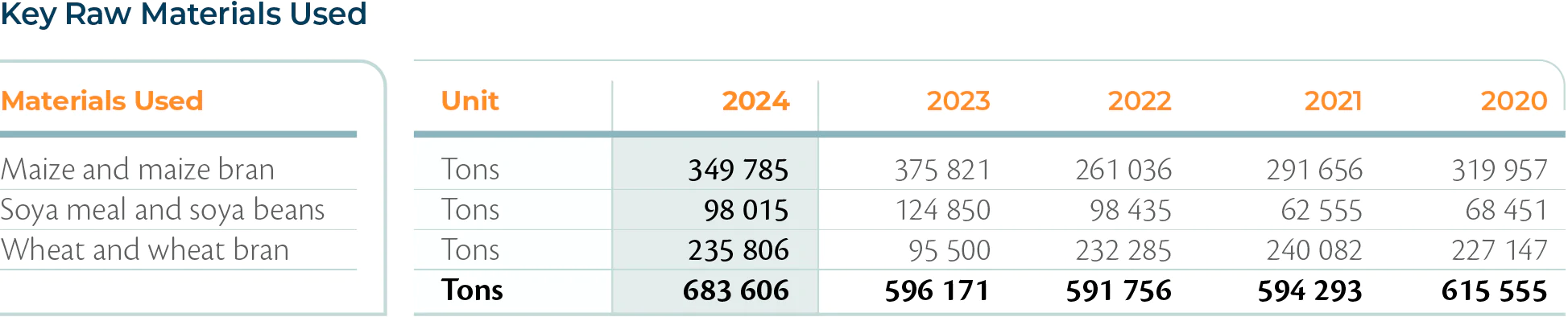

The Group’s key raw materials are maize, wheat, wheat bran, soya meal and soya beans. The quantities required by the Group are significant and the table below highlights the volumes consumed each year in the production of our products.

Management Approach

The Group’s approach to raw material management starts from procurement to storage and the production process. Our procurement policy requires that raw materials are tested and screened to ensure the right materials are sourced. Any waste from the production process is recycled, where possible, to reduce the amount of final waste that requires disposal. We endeavour to find alternative use of waste materials. Our goal is to maximise environmentally and socially responsible raw material use.

Local Procurement

The Group is committed to developing relationships with local partners and supporting local suppliers by sourcing locally produced materials, including medicines, whenever possible. This approach brings multiple benefits to the Group, such as enhanced reliability of supplies, reduced transport needs (thus lowering our carbon footprint), and minimised global supply challenges. In turn, this improves overall supply chain resilience and promotes economic growth by creating local job opportunities.

In addition, the Group’s procurement policy specifically prioritises sourcing from within the community to benefit local suppliers and ensure a consistent supply of essential products, including locally manufactured medicine. By focusing on local procurement, we contribute to building a sustainable and resilient supply chain that supports both our operational needs and the surrounding communities.

During the year, the Group’s procurement spend was as follows: